From lightweight manufacturing to complete dematerialisation through VR

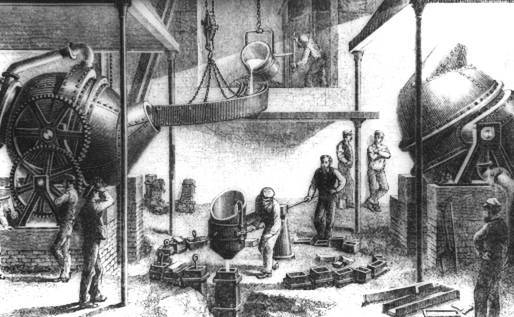

Coalbrookdale in Shropshire is often noted as the birthplace of Britain’s industrial revolution. More specifically: it was innovations in the iron ore smelting process and the consequent cast iron manufacturing that—quite literally—created the building blocks for 18th & 19th century industrialisation in Western Europe. This is the period that witnessed the construction of great bridges and viaducts, imposing factories, domineering steamships and other important endeavours.

Heavy industry, as it’s now known, is still largely associated with these activities. Steel has replaced Iron as the primary industrial material, allowing for longer spanned bridges, taller buildings and faster transport, but there is still substantial ‘weight’ attached to the products of this process. And along with weight follows environmental costs in terms of carbon emissions and habitat loss – ultimately this leads to further climate change related wreckage and the reduction of ‘real’ wilderness.

The extraction of resources and the transportation of raw materials inevitably leads to grave environmental damage. This is why product weight becomes an important consideration. Raw materials require sufficient energy to extract, process and transport. Some materials are, of course, more problematic than others. A tonne of aluminium requires vastly more resources to produce than a tonne of glass, for example. Conversely, glass, concrete and steel are used much more extensively in construction projects and therefore may have a particular negative impact overall; aluminium can be easily recycled. So, the relationship between product weight and environmental impact is complex.

Buildings and construction projects have, traditionally, had the greatest negative impact, from an embodied energy point of view, but also from an operational perspective. Buildings also have additional externalities in the form of roads, transportation, sewage and other such infrastructure used for servicing them. So, doing away with unnecessary construction would go a long way in reducing carbon emissions. But, more on this later!

The 21st century has brought on great advancements in material science. Ever lighter, stronger materials could potentially bring some much needed respite in carbon emissions. With the discovery of the ‘wonder material,’ Graphene, by scientists at the University of Manchester—a global centre for research in material science—all manner of exciting possibilities await us. Yet, this ‘lightweight manufacturing’ wave could be subsumed by an even larger ‘dematerialisation’ wave that has accelerated as a result of late 20th century advancements in silicon technologies and digital network infrastructure.

Dematerialisation is where stuff, rather than simply getting lighter, actually disappears completely as a result of being rendered irrelevant! For example, it would take an entire van full of 3.5 inch 1.44mb floppy discs, weighing nearly 400kg, to equal the amount of data that can be stored today on a tiny 32gb pen drive. Another interesting example is that of public telephone booths. The iconic K6 telephone kiosk, designed by Sir Charles Gilbert Scott, stood 8ft tall and weighed around 750kg, but is now mainly used by weekend revellers as a urinal substitute! The ubiquity of mobile phones has made these booths irrelevant.

The English version of Wikipedia holds the equivelent of 2750 volumes of Encyclopedia Britannica and is accessed by around 70 million unique visitors a day. The stats for YouTube are even more mind boggling: over a billion hours of video content is being viewed on the site daily; that’s the equivelent of 500 million T-120 VHS cassette tapes! The Internet is basically one collossal dematerialiser. The trend towards virtualised servers, cloud computing and software as a service (SaaS) further kills the need for ‘ownership,’ resulting in yet more efficiency. The popularity of services like Netflix and Spotify reflects this societal shift towards renting digital products as opposed to owning physical stuff. Efficiency in product delivery means substantial cost savings, but potentially also better environmental outcomes. I say ‘potentially’ because there are some complications in this scenario.

An 8:40am stroll past any school in a typically middle class suburban neighbourhood will quash any notion that products inevitably get smaller, lighter and more efficient. With hoards of mums and dads lining up in their Porsche Cayennes and other diesel guzzling, ‘sport utility vehicles’ – it really does put things in perspective. Even the earlier example of YouTube requires some reassessment: endless ‘crazy cat videos’ or other similar memes would never have shifted many video cassettes or DVDs! So, we need to be realistic about any actual ‘weight loss’ that can be delivered through dematerialisation. The fact is that human nature is such that savings in one sphere can open up potential for consumption in other areas.

When stuff gets virtualised, even while some physical weight is eliminated, it massively increases data over networks. Sophisticated data centres are required to handle all this. Which presents us with the other complication: data centres require lots of energy to run and have other externalities. For any environmental benefits to materialise, the energy delivered to these data centres needs to, at the very least, come from renewable sources. Server and network technology is, however, quickly moving in the right direction, in terms of speed and efficiency.

When seen from a glass half full perspective, the cutting off of ‘fat’ can bring about both environmental and commercial savings. Bell Helicopters, for example have reportedly brought their sleek new FCX-001 helicopter 10 times faster to market by introducing VR technologies in their design flow. That is huge! But how? Well, rather than the slow ‘heavy’ process of getting physical mockups made, they ‘built’ VR models instead, allowing super-fast design iterations.

VR is the ultimate dematerialiser: entire shopping malls could be written off, university lecture halls made useless, trade exhibition halls no longer needed; the possibilities are endless. None of this means that construction ceases; certainly not! In fact, new architectural programs might be explored - ones that add greater value to life in the 21st century. Rather than the sterile, patchy greenery we find in our towns and cities, the absence of wasteful bulky architecture and other ‘energy sinks’ could lead to opportunities for cultivating natural habitats, parks, lakes or even some real wilderness.

Closing Comments:

While ‘lightweight manufacturing’ could certainly lead to more efficient, environmentally sustainable products, ‘virtual manufacturing’ reduces weights down to zero! This can lead to significant benefits, as noted above. For this to materialise, however, individuals and organisations should be open to opportunities where the need for physical stuff (real estate, machines etc) is eliminated by ‘virtualising’ wherever possible. The pace of growth seen in VR and related technologies point to a future where this would not only be possible, but also desirable.